– Spray Skin is technology of spraying a high-quality face polyurethane coating (artificial leather) with a film thickness of 0.8 mm with various color solutions.

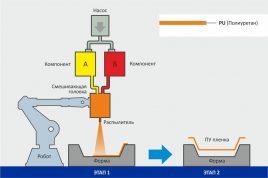

Spray Skin process

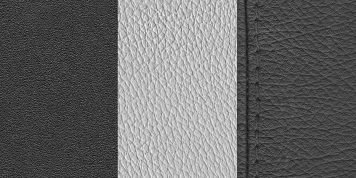

Variants of embossment on the part front surface

Application:

Interior parts face surface – instrument panel, upholstery (door /pillar trim), instrument panel console, floor mats, frontend insulation, etc.

Advantages:

- Wide opportunities of design;

- «Soft touch» effect;

- Various color solutions;

- UV resistance;

- Wear and tear resistance;

- High indicators of physical and mechanical characteristics (elongation, breaking load, etc.);

- Alternative to vacuum forming of the product face surface;

- Not very high level of investments in production preparation;

- Project start up from 3 months.