– PDCPD – RIM – Technology. Dicyclopentadiene (DCPD) is used as initial component.

Polydicyclopentadiene (PDCPD) – it is a material that can replace metal, fiberglass and a number of polymers due to its unique properties. It has low density, high impact resistance, which is retained even at low temperatures (-60 ° C), as well as high resistance to aggressive media, benzo-oil resistance. There are practically no size and thickness limitations.

The material is easily processed, glued and painted.

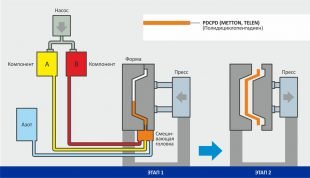

PDCPD process

Variants of manufactured products

Application:

- Fenders, , door trim, body elements, technical component inside engine compartment;

- Chemical and electrochemical industry: containers, tanks;

- Agricultural machines, tractors and loaders: bumpers, fenders, claddings, hoods, cabin elements, etc.;

- Trucks/cargo transport: bumpers, side panels, spoilers, claddings, deflectors, tanks, etc.;

- Passenger transport (buses, minibuses): bumpers, side panels, spoilers, wheel arc cladding, deflectors, linings, cladding panels, etc.;

- Other: drainage elements, sewage caissons, , barrel partitions, road arcs, tanks, containers.

Application:

- Simple scheme of mixing components;

- Decreased cost of tooling production due to the technology process: pressure inside the mold at filling is not more than 2 atm is maintained, the tooling material is aluminum, steel or composite;

- Short reaction time – less than 60 seconds;

- Not very high level of investments in press forms;

- Project start up from 1 month.